Research & Test

In addition to reference method gas analysers, Signal Group also manufactures a full range of sample handling, calibration and test instruments.

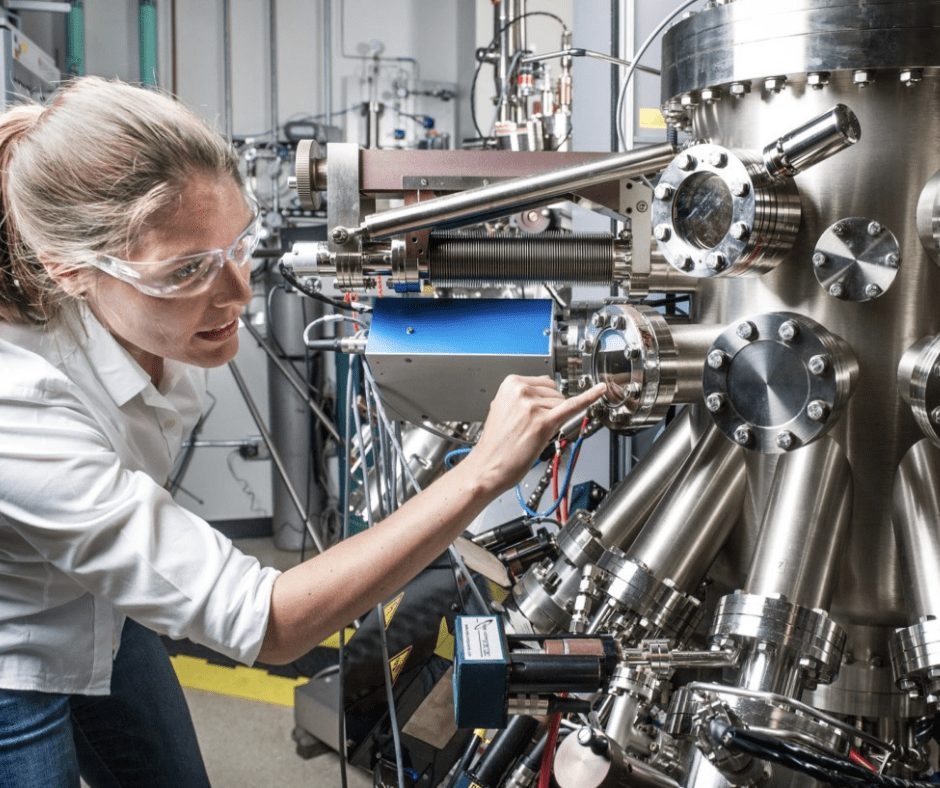

One of Signal Scientech's core competencies is the manufacture of gas analyzers for combustion testing and research. The company's wide range of products has been developed over the years; Work closely with clients to meet research, market and regulatory requirements. Usually, this research is carried out in the departments of thermodynamics, chemical engineering, mechanical engineering, environmental engineering, catalyst research, etc., of the university. In addition, manufacturers of fuel burning equipment such as aviation gas turbines use Signal Scientech analyzers for research and development, stationary diesel engines, off-highway diesel engine vehicles, incinerators, boilers and stoves.

Signal Scientech's comprehensive product portfolio enables the company to offer individual analyzers or complete custom systems in turnkey contracts with maintenance agreements and scheduled service access. The long-term, mutually beneficial partnerships established between Signal Scientech and its customers have become a core strength of the business. With a deep understanding of technical requirements, Signal Scientech often provides additional analyzers, test/calibration equipment and sampling lines to enhance the capabilities of customers' experimental test benches.

SOLAR

Flame Ionisation Detector (FID) VOC analysers for gas purity, air separation, engine emmisions, combustion studies and process plant VOC abatement monitoring

- ELECTRONIC PROPORTIONAL BAND FLOW CONTROLLERS

- AUTOMATIC FLAME OPTIMIZATION PROGRAM

- AUTOMATIC CALIBRATION

- SPECIAL HIGH EFFICIENCY HC CUTTER

PULSAR

Non Dispersive Infrared (NDIR) Multi-gas analysers are available in 1, 2, 3, 4 or 5 gas channel configurations, offering high levels of performance and flexibility. Options include CO, CO2, CH4, NO, N2O, SO2, HCl and O2.

- LOW RANGES E.G. 0-10 PPM CO

- 5 USER-CONFIGURABLE RANGES + AUTORANGE PER CHANNEL

- ELECTRONIC PRESSURE & TEMPERATURE COMPENSATION

- RS232 'AK' PROTOCOL, 4-20MA & 0-10VDC CHART OUTPUTS